Unlocking Efficiency: The Benefits of Prefabrication in Construction

In the realm of modern construction, efficiency is paramount. With the demand for rapid completion, cost-effectiveness, and sustainability on the rise, traditional construction methods are facing significant challenges. In response, the construction industry has turned to prefabrication as a solution to streamline processes and overcome these hurdles. Prefabrication, the practice of assembling components of a structure in a factory or other manufacturing site and transporting them to the construction site for installation, offers a myriad of benefits that revolutionize the way we build. Let’s delve into some of the key advantages of prefabrication.

First and foremost, prefabrication significantly reduces construction time. By manufacturing building components off-site concurrently with on-site foundation work, project timelines are greatly accelerated. This simultaneous construction approach minimizes overall project duration, enabling developers to meet tight deadlines and expedite occupancy. Moreover, prefabricated elements are meticulously crafted in controlled environments, free from the constraints of weather conditions and other external factors that commonly impede traditional construction progress. As a result, delays are mitigated, and project schedules remain on track, ultimately saving both time and money.

In addition to time efficiency, prefabrication offers unparalleled cost-effectiveness. The economies of scale achieved in factory settings, coupled with optimized material usage and reduced labor requirements, result in significant cost savings compared to traditional construction methods. Furthermore, the precise engineering and assembly processes inherent in prefabrication minimize material waste, thereby reducing overall project expenses and contributing to a more sustainable construction industry. These cost efficiencies not only benefit developers but also make construction projects more accessible and affordable for a broader range of stakeholders.

Prefabrication also enhances construction quality and consistency. With components manufactured in controlled environments using advanced technologies and stringent quality control measures, the risk of defects and inconsistencies is significantly reduced. The precision and repeatability of prefabricated elements ensure uniformity across the entire structure, leading to superior craftsmanship and long-term durability. Additionally, prefabricated components are often engineered to meet or exceed industry standards and regulatory requirements, enhancing overall building performance and safety.

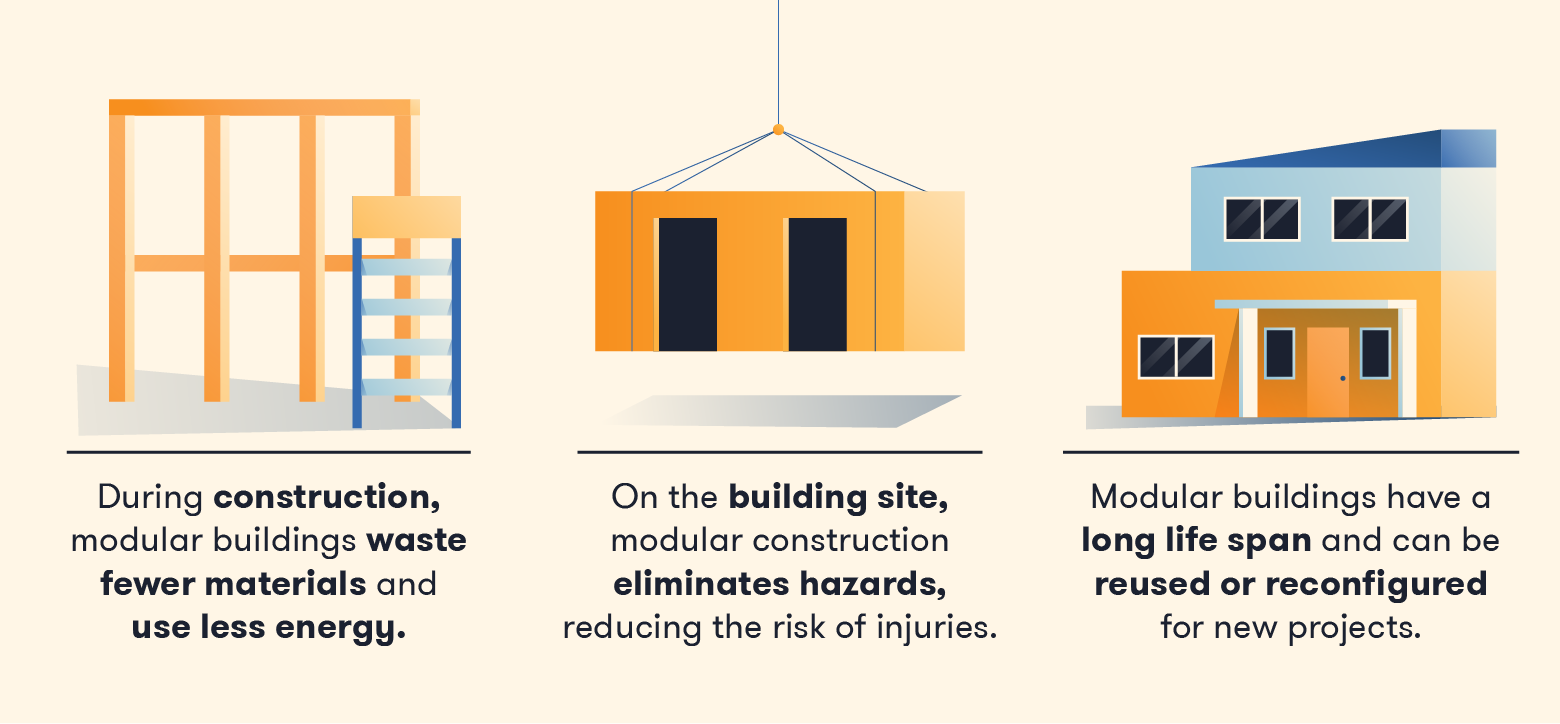

Furthermore, prefabrication promotes sustainability by minimizing environmental impact throughout the construction process. The controlled manufacturing environment allows for efficient use of resources, including materials, energy, and water, while also reducing emissions and waste generation. Additionally, the ability to prefabricate building components off-site reduces disturbance to the surrounding environment, mitigates noise pollution, and minimizes transportation-related carbon emissions. As sustainability continues to be a top priority in the construction industry, prefabrication emerges as a key strategy for achieving green building goals and reducing the sector’s ecological footprint.

In conclusion, the benefits of prefabrication in construction are undeniable. From accelerated project timelines and cost savings to enhanced quality and sustainability, prefabrication offers a holistic approach to modernizing the construction process. As the demand for efficient, cost-effective, and sustainable building solutions continues to grow, prefabrication stands at the forefront, reshaping the future of construction and unlocking new opportunities for innovation and progress.

Certainly! Delving deeper into the benefits of prefabrication in construction reveals a nuanced understanding of its transformative potential. Let’s explore these advantages further:

Enhanced Project Planning and Design Integration

Prefabrication necessitates detailed planning and design at the initial stages of a construction project. This upfront investment in design and engineering encourages collaboration among architects, engineers, and contractors, fostering a more integrated approach to construction management. Through the use of Building Information Modeling (BIM) technology, stakeholders can visualize the entire construction process, anticipate challenges, and make informed decisions early on. This proactive planning reduces the likelihood of costly and time-consuming errors during construction, ensuring smoother project execution.

Safety Improvements

The controlled factory environment inherent in prefabrication significantly enhances worker safety. Unlike traditional construction sites, where workers are exposed to various hazards, including adverse weather conditions, working at heights, and on-site accidents, prefabricated construction minimizes these risks. Manufacturing facilities are equipped with advanced safety equipment and ergonomic working conditions, reducing the incidence of workplace injuries. This not only leads to a healthier and safer workforce but also decreases the potential for project delays related to safety incidents.

Labor Efficiency and Skilled Workforce Utilization

Prefabrication addresses the construction industry’s challenge of labour shortages by making more efficient use of the available workforce. The factory setting allows for the employment of specialized labour, streamlined production processes, and the use of automation and robotics, which can perform repetitive tasks more efficiently than manual labour. This efficient allocation of labour resources helps mitigate the impact of skilled labour shortages and reduces the dependence on a large on-site workforce, which can be particularly beneficial in regions facing labour constraints.

Flexibility and modularity

Prefabricated construction offers remarkable flexibility in design and can accommodate a wide range of architectural styles and building types. The modular nature of prefabricated components allows for easy expansion or reconfiguration of buildings to meet changing needs or preferences. This modularity is especially advantageous in sectors such as education and healthcare, where evolving demands require adaptable infrastructure. Additionally, prefabrication enables the disassembly and relocation of structures, presenting a sustainable option for temporary or mobile facilities.

Reduced site disruption and community impact

Traditional construction activities often cause significant disruption to the surrounding community, including noise, dust, and traffic congestion. Prefabrication minimizes on-site construction time and activity, thereby reducing the impact on local residents and businesses. This is particularly beneficial in urban areas or sensitive environments where minimizing disruption is a priority. By shifting the bulk of construction activities off-site, prefabrication contributes to a more harmonious relationship between construction projects and the communities they serve.

Long-Term Sustainability and Energy Efficiency

Beyond the immediate environmental benefits of reduced waste and resource efficiency, prefabricated buildings often exhibit superior energy performance. Precision in manufacturing ensures tighter fits and better insulation, which can lead to significant energy savings over the building’s lifetime. Furthermore, the ability to integrate advanced materials and technologies during the manufacturing process allows prefabricated buildings to meet higher standards of energy efficiency and sustainability.

In essence, the shift towards prefabrication in construction is not merely a trend but a paradigm shift, reflecting a broader movement towards efficiency, sustainability, and innovation. As the construction industry continues to evolve, prefabrication stands out as a key strategy for addressing contemporary challenges while paving the way for a more sustainable and efficient future in building design and construction.